The Benefits of Plasma Cutters

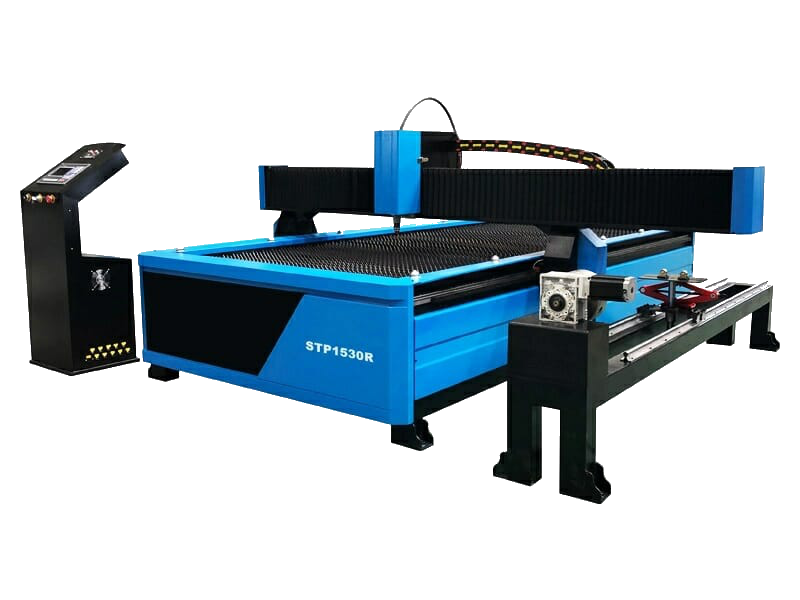

Plasma cutters offer numerous benefits. First, plasma cutting is faster than most other methods of cutting metal, meaning that more work can be done in less time with fewer errors. Moreover, because it uses directed arcs of extremely hot gas rather than blades or machining tools, it produces more precise and clean cuts on material such as steel or aluminum.

Additionally, there is virtually no distortion with plasma cutting compared to other methods like oxy-fuel flame cutting or water jet cutting. This precision makes plasma cutters crucial for many jobs requiring accuracy or complex shapes — such as automotive design and aerospace engineering tasks — that would be difficult if not impossible using other means.

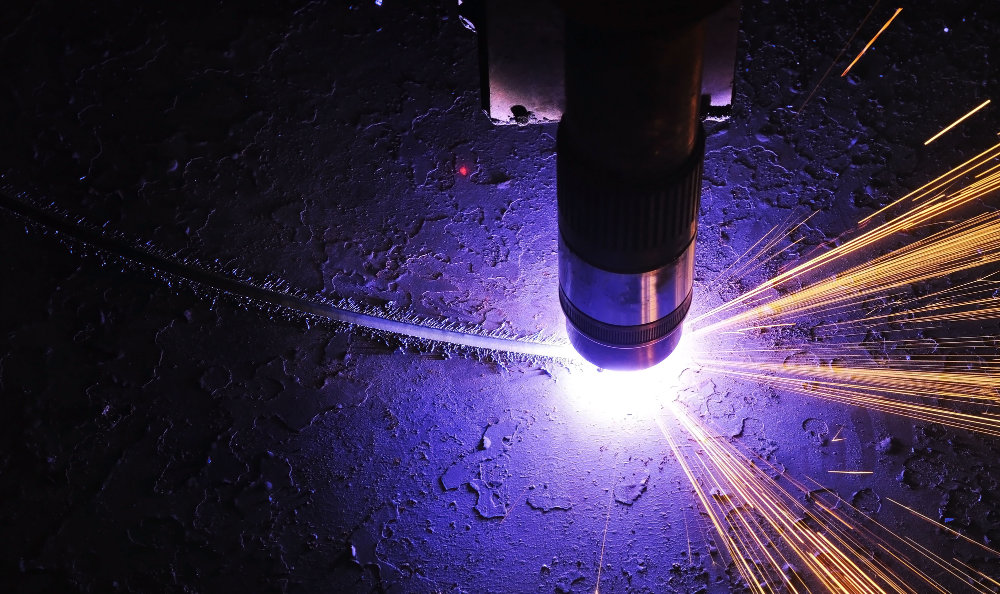

How Do Plasma Cutters Work?

At its core, the process of plasma cutting relies on the heat created by electricity running through gases like nitrogen and argon enclosed in a small torch head which has been specially designed for this purpose. In essence this creates an arc that produces temperatures of up to 30 000°C/ 54 000°F!

This arc then melts away whatever material it is focused on with ease – from thinner metals such as aluminum all the way up to 1″ thick steel plate! As the arc does its work it also blows away the molten metal leaving behind a clean edge – perfect for any welding job!

Plasma Cutting & Welding

Metal Manufacturing & Fabrication

Business Signs & Logo's

Outdoor Yard Decorations

Welcome Signs

Skyline Silhouette of Nature

Get a Quote For Your Project

Contact Us

Phone

(513) 839-3722